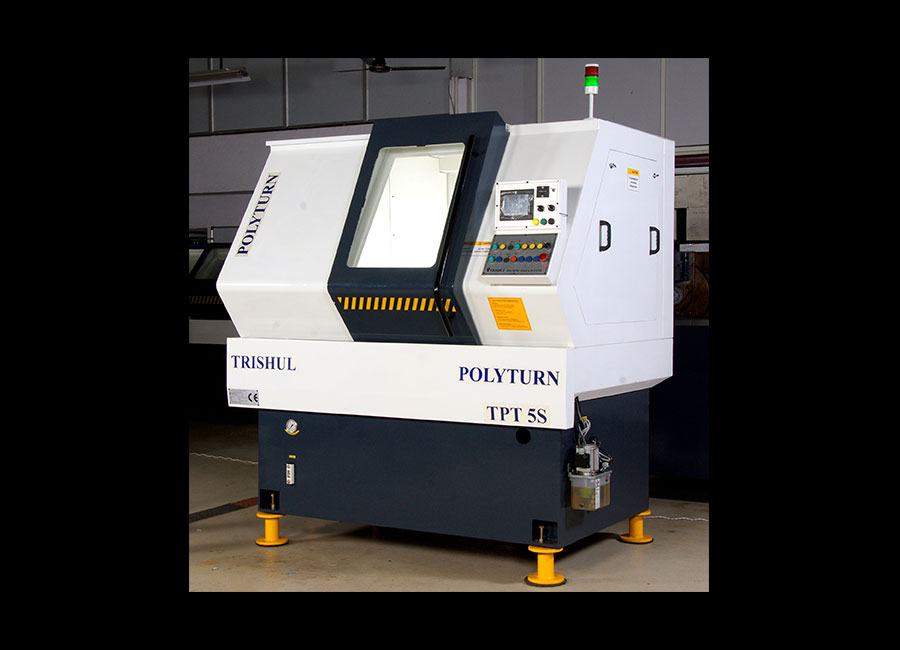

Model: TPT-5S

Another sophisticated model that is primarily useful to machine polar arrayed features like the ones found on Ratchets, splines and serrations.

The three axes X, Y, and Z are driven by servomotors. The state of the art motion controllers regulate the precision and accuracy. The Work Spindle and Tool spindle is driven by a sophisticated motion controller with Electronic Gear Box. The Spindles have a very unique feature to stop in sync during power failure.